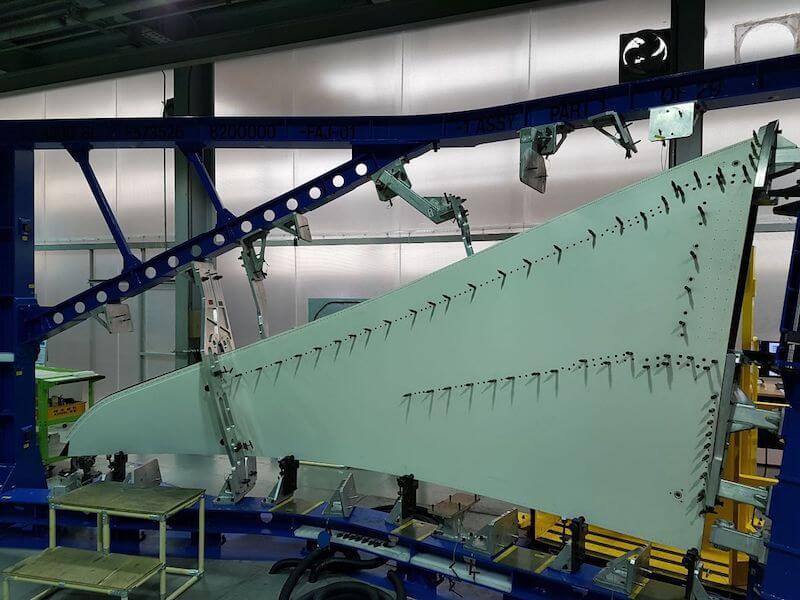

Toulouse, October 6, 2017: As Airbus prepares for the first flight of the A330-900, production of the second member of the A330neo Family, the A330-800, is well underway with the first parts advancing at Airbus sites throughout Europe. These parts include the new increased-span wing now being equipped in Bremen (Germany) and its new composite Sharklets from Korean Air Aerospace Division (KAL-ASD), the fuselage sections in Hamburg (Germany), the new titanium pylons in Toulouse (France) and the center wing box in Nantes (France).

A330neo

Production of A330-800 will continue towards start of final assembly by the end of 2017 gearing up to first flight in 2018.

Building on the success of the A330-200 with over 600 aircraft in operation, the A330-800 brings new generation economics and comfort in addition to unprecedented range to the 250-seater aircraft market. Together with the larger 300-seater A330-900 they share 99 per cent of commonality, having the same airframe, engines and cross crew commonality giving operators a great flexibility to use both aircraft in their networks. All A330s are built on the same production line so orders can be fulfilled in full flexibility according to market demands.

Airlines will benefit from 14% less fuel burn per seat compared to the current A330, reduced maintenance costs and A330’s market-leading 99.5% operational reliability. Passengers will enjoy the award-winning all new Airspace cabin inspired by the A350 XWB and an exceptionally quiet flight.

Production of A330-800 will continue towards start of final assembly by the end of 2017 gearing up to first flight in 2018

With close to 1,700 orders, the A330 is the most popular wide-body aircraft ever, having flown nearly 1,000,000 annual flights. Today, over 1,300 aircraft have been delivered to 117 customers worldwide.

Source: Airbus